EDS macht Druck bei der Funktionssicherung drucktragender Armaturen mit EDS Turbo-Rückschlagventilen

Schon 1995 begann Kompressorentechnik-Experte Kaspar Emunds mit der Entwicklung besonders strömungsgünstiger, wartungsfreier Rückschlagventile. Die patentierte Technik liegt mittlerweile einem 225 Ausführungen umfassenden Sortiment an Rückschlagventilen zugrunde, die weltweit ihre Abnehmer finden.

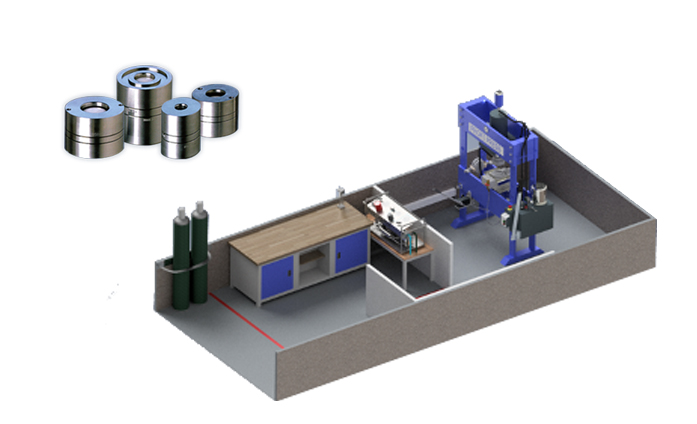

Der von Junior Martin Emunds eingeführte, und auf den neusten Stand gebrachte, Prüfstand für Armaturen mit Rückschlagventilen ermöglicht die Abnahme der Anlagenbauteile nach der Druckgeräterichtlinie 2014/68/EU. Aufbau und Durchführung der Prüfsequenz erfolgen nach DIN EN 12266-1:2012-06 – ein mit der Druckgeräterichtlinie konformer, praktischer Leitfaden zur Umsetzung der Prüfung.

Der Prüfstand ist für Armaturen bis zu einem Außendurchmesser von 160 mm (DN100) konzipiert und kann einen maximalen Prüfdruck von 600bar sowie einer Einspannkraft von 98 kN aufbauen. Er entspricht damit die anspruchsvollsten Nutzungsbedingungen von Kompressoren z.B. in der Öl- und Gasproduktion, Raffinerien und der Lebensmittelindustrie.

Im Falle einer Festigkeitsprüfung des drucktragenden Gehäuses wird der Prüfdruck mit dem Medium Wasser über eine Handpumpe erzeugt. Für die Prüfung der Dichtheit des Gehäuses und der inneren Dichtheit (Dichtsitz und Dichtkörper) wird gasförmiger Stickstoff über eine Verdichterstation aufgebracht.

Da sich die Vorteile von EDS Turbo-Rückschlagventilen bei Nutzern leistungsstarker Kompressoren längst herumgesprochen haben, läuft deren Produktion in unserem Werk auf Hochtouren. Auch unser Prüfstand beweist sich im alltäglichen Gebrauch und sichert die herausragende Belastbarkeit unserer Produkte.

Sie möchten mehr über unsere Turbo-Rückschlagventile erfahren? Fragen Sie uns nach den geeigneten Ausführungen für Ihre Armatur!

Comments are closed.